-Ham Madde Hazırlığı

Talep edilen koşullarda kalite kontrolleri yapılmış, öğütülme ve homojenleştirme işlemleri tamamlanmış, metal dedökterlerden geçirilerek taraması yapılmış, tartım gibi ön işlemleri bitirilmiş olan üretilmesi planlanan ürün; ham peynir, tereyağ, katı-sıvı yağlar, çeşitli tozlar ve suyun karışımı ile oluşmaktadır.

-Proses İşleme

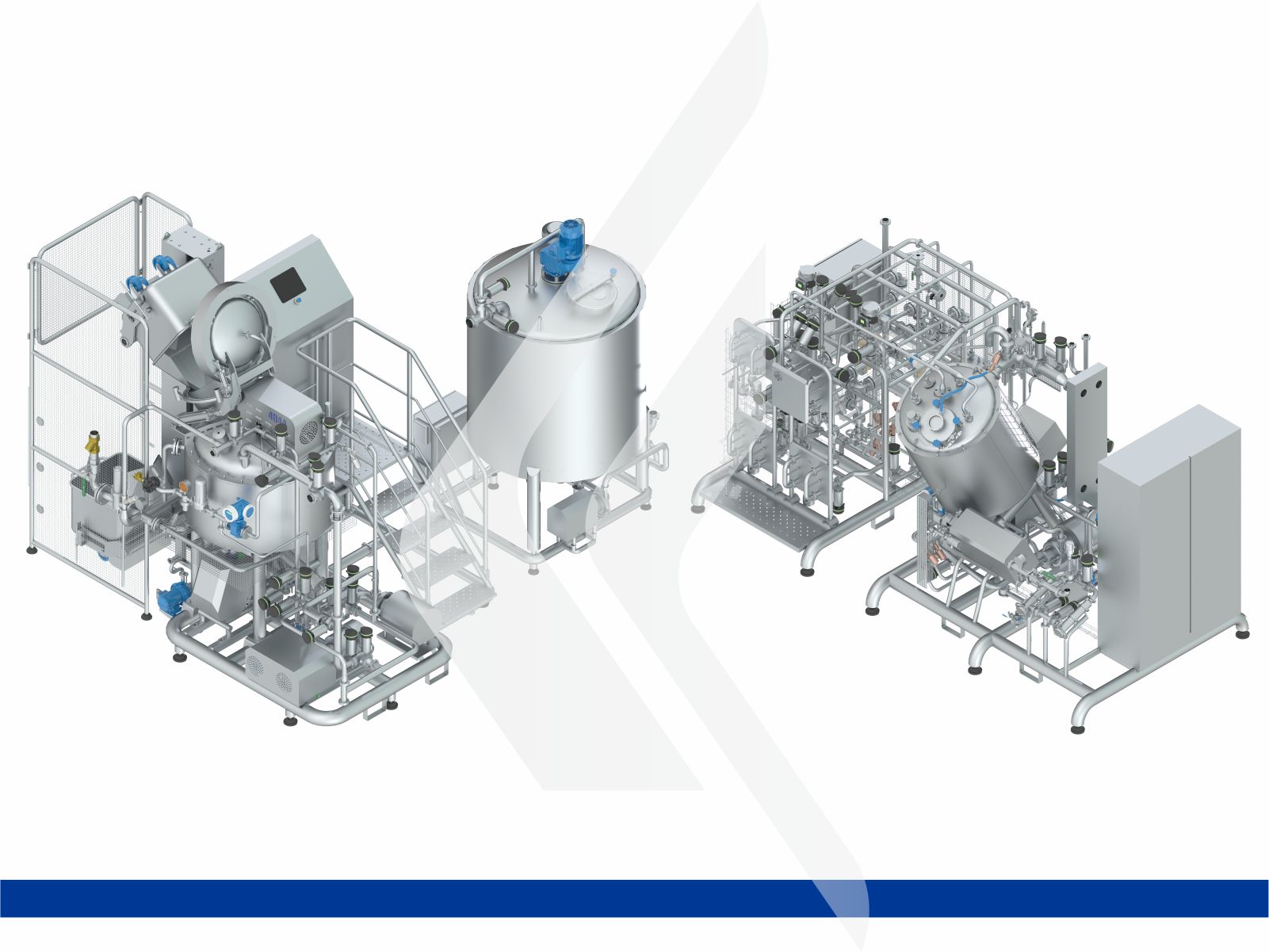

1-Ön Isıtma/Homojenleştirme

Batch ısıtma sisteminde, doğrudan buhar enjeksiyonu ile ısıtma ve emülsifiye etme, kesme, karıştırma, havasını alma gibi tüm işlemler tek bir ünitede(KR-500)yapılır.

2-UHT

UHT günümüz teknolojisinde bir çok farklı ürünü aynı sistemde işleyebilme ve üretebilme kapasitesine sahip son teknoloji sistemlerdir. Bu sistemde üretilen ürünler 145 C’ye kadar ısıtılabildiği için raf ömürleri muadillerine göre iki kat daha fazladır. Uzatılan bu raf ömürü süreleri için UHT sistemi kullanılmaktadır.

Isıtma sonrası sıcaklıktan dolayı borularda oluşan yapışmayı engellemek için ürün ile temas eden boru yüzeyleri PTFE(teflon) kaplanmıştır.

Dolum öncesinde, kontrollü vakum ile ürünün soğutulması ve havasının alınması gerekmektedir.

Devamında ürün yapısının tekrar oluşturulması ve vizkosite gelişimi için kremleştirme tankı kullanılır.

Kremleştirme Tankı vizkosite izleme donatılı, yüksek verimli bir karıştırma elemanıdır.

CIP, buhar filtrasyonu, ürün filtrasyonu sistemleri için ilave modüller mevcuttur.

Özellikler

-Sistem süt işleme endüstrisinin ihtiyaçları esas alınarak tasarlanmıştır.

-Peynir işlemede hassas ve tam kontrol

-Kısa ve etkili işleme süreçleri ile kaliteli üretim

-Müşteri ihtiyacına göre esnek ve er; GOnomik tasarım

Avantajlar

-Doğrudan buhar enjeksiyonu ile etkili ısıtma

-Kolay kullanım

-Çalışma sürelerinde artış

-CIP kolay temizlenebilirlik

-Sabit ürün kalitesi

-Vizkozite kontrol sistemi

-Yeni pazar ihtiyaçlarının karşılanması

-Kolay bakım

Uygulamalar

-İşlenmiş Peynir (Sürme, Kalıp, Dilim)

-Anolog Peynir

-Bebek Maması

İşlemler

-Emülsifiye(KR 500)

-Karıştırma(KR 500)

-Pastörizasyon(KR 500)

-UHT

-Hava alma(Ön Soğutma)

-Vakumla soğutma-temizleme(Ön Soğutma)